Jig and Fixture Manufacturers in Chennai | 9994526490

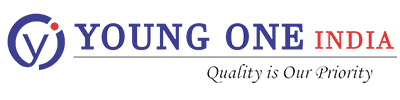

Masters of Accuracy Jig and Fixture Manufacturing at its Best

Advance Technologies is one of the best Jigs and Fixtures Manufacturer in Chennai, built and manufactured in different shapes and sizes according to customer requirements. They provide the customers with the highest and best quality material which not only gives them satisfactory but also excellent performance.

We’re committed to being the best Jigs and Fixtures Manufacturer in Chennai. Such jigs and fixtures are commonly used in the automotive industry and are produced using advanced manufacturing technologies and components tested for consistency. Such jigs and fixtures are provided in a range of configurations according to our clients’ unique requirements and made available at industry-leading prices.

Tailored Tools for Precision Work with Jig and Fixture

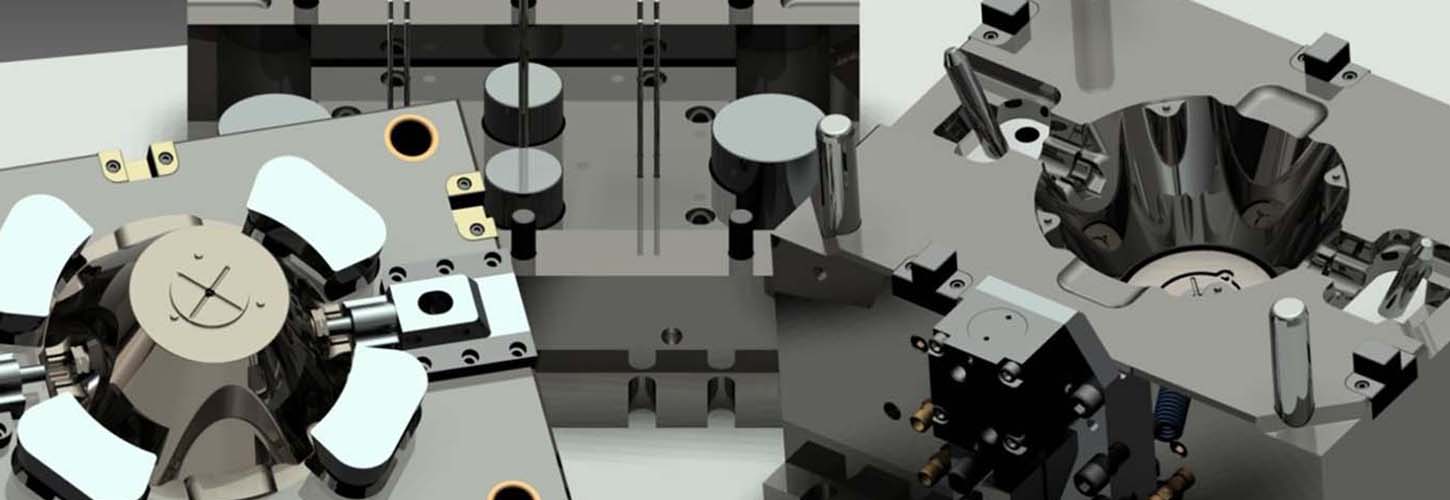

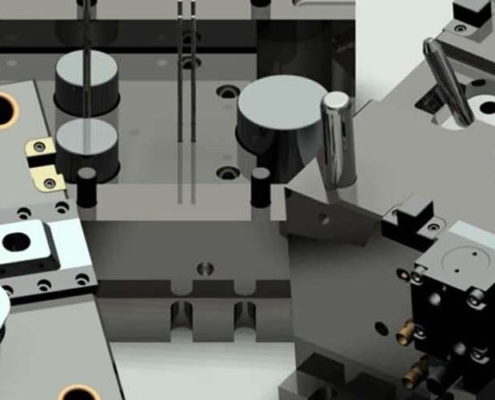

Using state of the art technology, our Jigs and Fixtures Manufacturer in Chennai continue to provide our customers with the newest and most convenient goods. We are backed by an appropriate network for our customers to deliver the highest quality goods.

Our Jigs and Fixtures Manufacturer in Chennai sources the quality assured products from our trusted and reliable suppliers for quality assurance.

The raw materials and components used in your jigs and fixtures are of high quality. This commitment to quality is crucial for delivering reliable and durable products to your customers. By working with trusted suppliers, you build a strong foundation for your manufacturing process, ensuring that your products meet the highest standards. This emphasis on quality assurance sets your business apart and instills confidence in your customers, making your Jigs and Fixtures a reliable choice in the market.